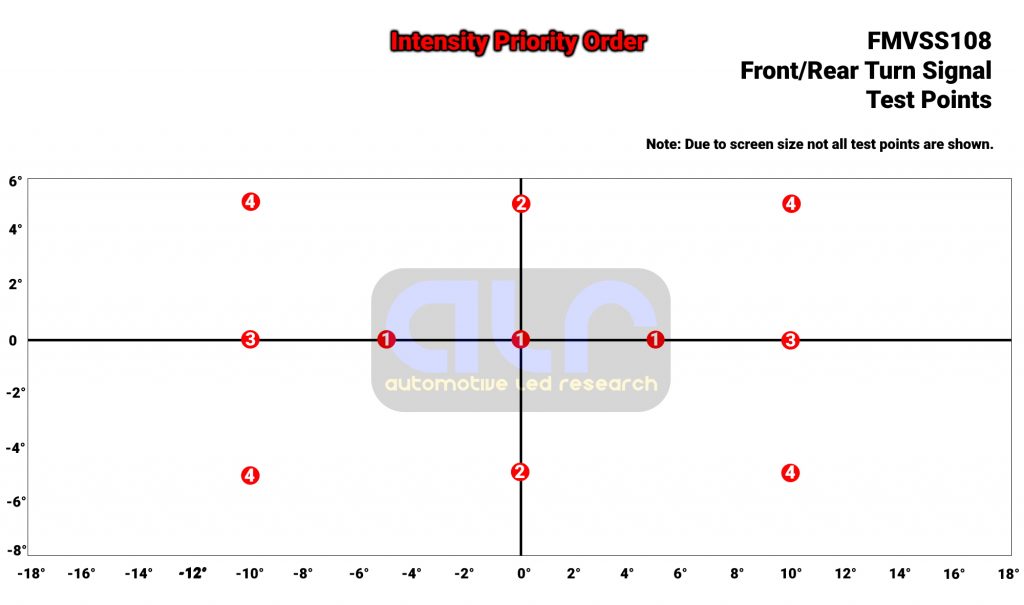

Testing Protocol

Illuminance measurements were all taken at an approximate distance of 5.1 meters from bulb filament to test screen. Voltage was regulated at 13.7v to represent real world median line voltages. Test points on screen represent the turn signal photometric requirement angles as defined in the FMVSS108 regulation. The primary test points that hold the highest minimum intensity requirements is located in the middle five test points (numbered 1 and 2) which I will call the “priority center zone”.

*Several test point angles from regulation were excluded from this test due to being outside the boundaries of the test screen.

Light pattern evaluation

Photos below show the incandescent on top and XTR VF LED at the bottom. Secondary view is with image enhancement revealing contours in the beam making it easier to compare light patterns.

10-18 Ram 1500 *headlamp*

19-20 Ram 1500 *headlamp*

15-17 Honda Accord sedan *headlamp*

16-19 Toyota Tacoma *headlamp*

16-17 Honda Accord sedan *tail lamp*

As seen in the photos above, the XTR VF LED more or less delivered on its optical promise with light patterns that are a near match to their incandescent counterparts. This cannot be said by any other AMBER LED bulb currently on the market today. And although there are undeniable nuances (subtle and not so subtle) in the shape of the new beam for each lamp, this is a huge step for the LED replacement bulb world. Reproducing the lamps beam shape is crucial to the safe visibility towards others as the light pattern was engineered to not only meet the minimum federal lighting standards but also the lamp manufacturers intended optical output design.

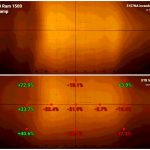

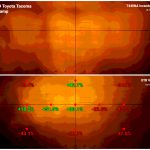

Test results

Rather than provide lux readings on a chart, I converted these measurements into +/- percentages against the original bulb measurements. I then superimposed those % readings onto the photos to their corresponding test point locations. Reviewing the data reflects some rather interesting information. Surprisingly the XTR VF LED fell short of matching the luminous intensity of the incandescent bulbs for the majority of the lamps. The 4th Gen Ram and the Tacoma were the only lamps that showed improvements at certain test point angles. The Honda Accord tail lamp was a bit perplexing at first. I couldn’t understand why this lamp appeared so weak even with the original bulb. It wasn’t until after I had completed all the testing that I realized that part of the reflector body was damaged. This was purchased used and I failed to fully inspect it. Most of the mirrored surfaces had some type of heat damage or something else which had degraded their high luster. This no doubt prohibited the full performance of the lamp. I decided to still include my findings anyway simply to demonstrate the optical capabilities of the XTR VF LED.

It should be noted that there are 3 different incandescent bulbs being used in this evaluation:

-

-

- 7444NA(WY28/8W)

- 3157NA (P27/7W)

- 7440NA(WY21W)

-

Listed in order from highest to lowest wattage, each of these bulbs has different power specifications which in turn results in slightly varying luminous flux output. The XTR VF LED faired a little better within the priority center zone in the single filament 21w 7440 lamp (Tacoma) but struggled much more in the 28w 7444 lamps ( Accord & 5th gen Ram) and 27w 3157 lamp (4th gen Ram). I suspect that possibly the Ram 3157 lamp showed improvements on the outer region test points because of the good back shoot of the XTR VF LED which may be reaching the inner reflector segments that correspond to the outer edges of the beam. With all this in mind we could arrive at the conclusion that the amber XTR VF LED needs more luminous power from its light source. Seeing that the light patterns had a very close resemblance to the original beams it would seem that amplifying the luminous output would improve the intensity performance equal to that or greater than the incandescent. I’m more interested now to see how much better it would have done with the Accord tail lamp, had it not been damaged, which uses the 21w bulb.

Let us now move on to see how the XTR VF LED stacks up against the competition. I chose a few readily available LED bulbs that you can pick up at your local auto parts store as well as a few popular cheap and expensive bulbs found online.

Bulb Type: 7440/7444

Bulb Type: 3156/3157

I think this puts into perspective of what performance is like in the current market of amber turn signal LED bulbs. This is what you can expect if you stick these in your vehicle. You’ve got the big names like Osram/Sylvania, Philips and of course the aforementioned VLEDS. The low power bulbs are pretty laughable and inexcusable if you ask me. The amount of light they put out is a joke and the scattered beams are just as humorous. Actually its not funny; its unsafe. I didn’t bother recording any measurements for the horrific Philips Ultinon bulbs because it was pointless. These types of weak LED bulbs have been circulating for years and up until recently there hasn’t been anything that is worth calling a true retrofit LED upgrade.

The VLEDS, while being a powerful bulb and with a virtual filament optic, doesn’t really offer any sort of favorable optical focus and that’s apparent in the photos. Most of its luminous output is coming directly out of the front of the optic. In lamps where the VLEDS did actually exceed at certain test points was merely incidental. A random angle or angles in the reflector where a portion of the VLEDS optical sweet spot just happened to bounce light off of. I say incidental because rotating this bulb moves all the blotches of light around in a circular pattern. You’ll either end up with good intensity at certain angles or you won’t. Its a luck of the draw. With this bulb being the old V3 version you can expect much of the same except twice the output for the new V6 amber. It’ll still have a kaleidoscope-type light pattern shining with no focused intensity anywhere like the lamp was designed to have.

Now, there is one bulb that stands out like a sore thumb in this bunch and that is the hyper-bright-no-resistor LED bulb sold under various brand names. There is no question this thing is extremely bright. Its damn near TOO bright. Its throwing light where it shouldn’t go. Its completely just overpowering the lamps reflector and using it as a flood light. If you look closely at the numbers you’ll notice a common theme with its performance. The priority center zone is its weakest area. It consistently has lesser intensity when compared against the outer test points. This is due to the obvious lack of central focus. Even though its luminous intensity at these angles exceeded the incandescent there just isn’t any refinement in this bulb. Its just a matter of sticking as many high power LED chips as you can on a small undersized heat sink, drive them to their maximum intensity and hope that your lamp will magically distribute all of it efficiently.

I know I probably sound like I’m repeating myself and that’s because I am. Optical focus is important. When others drivers are behind or facing toward your vehicle there are various viewing angles, distances, elevations and vehicle pitch angles to take account for. Your turn signal lamp was designed to focus its intensity towards all of these relevant viewing zones. Using an LED bulb that isn’t going to make use of the intended optics of the lamp is only diminishing its safety performance. Staring at the reflector section a few feet away from it may give the impression of brightness between bulbs but it isn’t until you move to farther distances that the focus breaks apart.

Final thoughts

I will first start off by saying that the fitment/compatibility phase of the testing proved to be the most disappointing. I would have preferred to have a large sample of both headlamps and tail lamps for testing but that just wasn’t possible. The well thought out thermal design of the XTR VF LED wound up impeding on its universal fitment capabilities. With hundreds of different style lamps out there now its hard to say for sure what percentage will fit and what won’t. Reducing its size without compromising thermal efficiency would be the first step in improving its potential for a higher fitment success rate.

I did not care for the loose fitment in some of the applications. The fact that I could twist and move the bulb out of focus with relative ease was a bit concerning since this left the possibility of having slightly inconsistent performance when removing and reinstalling multiple times. This however mostly applies in a testing environment and not so much in real world where someone is going to “set it and forget it” one time. Choosing one of the supplied rubber, foam or metal washers or a combination is required for a good firm fit depending on the application. The outer diameter of the collar is slightly too small in some cases which prevents the exact centering of the VF optic. The shifting of the light pattern can move a few degrees in any direction if not careful. And though the final results in this test still showed very good light pattern matches with little tweaking and adjustment of the fitment, I can’t help to think that they still could have been better.

Playing with the height of the recommended optical focal point was somewhat revealing. In certain lamps, moving the VF down a millimeter or two below the filament showed a slight gain in center intensity. Moving the VF up a few millimeters showed a loss in center intensity. Anything beyond that up or down resulted in a unfavorable beam pattern. Determining the exact setting for a specific lamp is extremely tedious because there are no reference lines on the bulb body. If one were to incorrectly position the VF at the improper height unknowingly then it may result in poor optical performance. This also holds true for the rotation. With no reference markings on the rear, under rotating or over rotating the bulb is easy to do. I think this eyeballing procedure should be substituted for a much more easier and precise way of performing the setting out of the box. This way its exactly set to the optimal height for your specific vehicle with no guess work.

Gripping the round heat sink fins made it difficult to lock the bulb in place. My fingers kept slipping off in instances where the bulb was a tight fit. There should be a wing nut or tabs at the very rear for the fingertips to be able to hold onto easily; just like some of the OEM bulb sockets. Being able to grip these bulbs firmly where access to the turn signal bulbs is in very tight quarters is a must.

Despite the XTR VF LEDs ability to mirror the original light patterns of all the test lamps, it just didn’t have enough power to really match or exceed the intensity on a consistent level across all test lamps. Switching to a higher luminous light source should give this bulb the boost it needs to be on par with the original incandescent output. Viewing the optical performance on the other hand is pretty remarkable considering its really the only LED bulb available that can do this. I feel that with just a few more tweaks to this design for both fitment and power the XTR VF LED could just very well be the best LED turn signal bulb you can buy. And even in its current format now it’s still a better bulb over what is currently offered on the market. Aside from the ridiculous hyper-bright bulb, the XTR VF LED actually reflected more intensity than the VLEDS in the priority center zone.

I need to be clear once more in case it wasn’t obvious to anyone reading this evaluation — my results are for only the AMBER color XTR VF LED. I have not tested the RED LED for stop lamps. This application may turn out to have better intensity performance versus the turn signal application. Red light emitted from an LED behind a red lens doesn’t get heavily filtered like it does with an incandescent bulb. The requirement for high output in red won’t be the same as it is for amber. And also, the likelihood for better fitment as a stop light bulb may have a higher probability. I just might test the red LED in the future to see if my speculation is accurate.