Overview

The XenonDepot Xtreme VF LED is a retrofit LED bulb that replaces the incandescent turn signal and brake light bulbs found in your headlamps and tail lamps. Unlike other typical LED bulbs where you simply swap out with the original bulb, the XTR VF LED is a complete module that replaces both the bulb AND socket. But what makes this LED bulb more unique than all others is its exclusive VF optic.

VF stands for Virtual Filament which is an optical element that sits on top of the LEDs and transfers the light to a new section. At the entry point when light is emitted through the optic, it is re-focused to a new single point and then dispersed or ejected outward to a desired pattern. This isn’t new technology though as its been around for quite some time, most notably found in older generation general purpose LED light bulbs. The idea behind it was to create a light bulb with an LED light source that mimics an incandescent bulb or rather the way an incandescent bulb distributes its light. Incandescent bulbs use a filament that produces an omnidirectional light which shines in all directions. An LED is a directional light source which shines forward in one direction. Developing a virtual filament optic helped solve the problem of turning an LED into an omnidirectional light source (to a degree).

For automotive lighting, Osram was the first to apply a virtual filament LED (which they called Joule) into a tail lamp to function as a brake/tail light bulb. It first appeared on the 2006 Mercury Mountaineer and 2008 Chevrolet Malibu LTZ eventually spreading to other Ford and GM models thereafter. It was primarily designed as an affordable solution to OEMs who didn’t want to spend a lot of money to have an LED tail lamp designed which requires more engineering effort. A tail lamp with a basic common reflector design and a plug-n-play LED replaceable bulb was the better choice for both cost and added safety. The downside to the Osram Joule is that it is vehicle model specific. It is not a universal bulb and you can’t just fit it to any incandescent tail lamp and expect it to perform as good. Both the reflector optics and virtual filament are designed to work together.

It first appeared on the 2006 Mercury Mountaineer and 2008 Chevrolet Malibu LTZ eventually spreading to other Ford and GM models thereafter. It was primarily designed as an affordable solution to OEMs who didn’t want to spend a lot of money to have an LED tail lamp designed which requires more engineering effort. A tail lamp with a basic common reflector design and a plug-n-play LED replaceable bulb was the better choice for both cost and added safety. The downside to the Osram Joule is that it is vehicle model specific. It is not a universal bulb and you can’t just fit it to any incandescent tail lamp and expect it to perform as good. Both the reflector optics and virtual filament are designed to work together.

The XTR VF LED uses this proven technology to fill the void in the aftermarket for anyone that wants a true LED replacement for their vehicle. But are they alone in this market? Not exactly. The popular brand VLEDS has had a similar virtual filament LED offering for a number of years called the Triton V3 and now most recently the Triton V6. This bulb has been widely revered by most as the brightest & best replacement LED bulb you can buy. You can say that they were officially the first to market such a bulb so it’s no surprise who the XTR VF LED is really competing against. There are a few other brands out of Russia also offering a virtual filament LED (HPL, ProBright and LightLabel) however their presence is not known by most North Americans because they do not market to this region.

So what makes the XTR VF LED different than the rest and how do they compare? Let’s take a closer look.

The optical element used in the XTR VF LED is completely different than its competitors which all use a typical cylindrical shape. The small thin pillar style optic has a concave cutout at the tip where the light converges but there is also a secondary optic in the form of a reflector cup that rests inside of it. This combination was engineered to provide the most accurate representation of an incandescent filament providing ample forward, side and rear shooting illumination. The reflector body inside a lamp is what is used to project the light forward into the designed beam pattern. The replacement light source, in this case LED, must be able to utilize all the reflector segments to maximize performance (reflector focus efficiency).

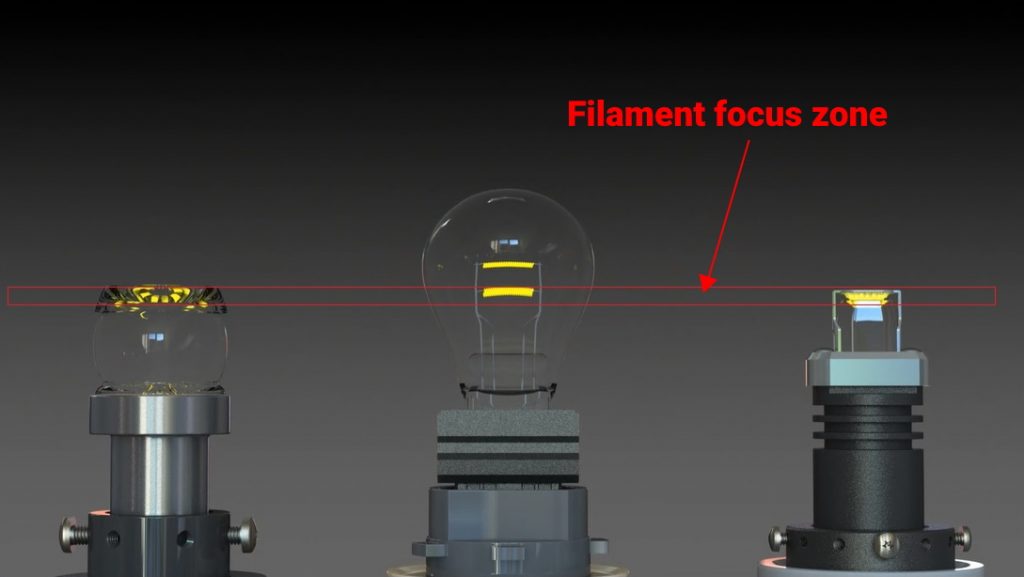

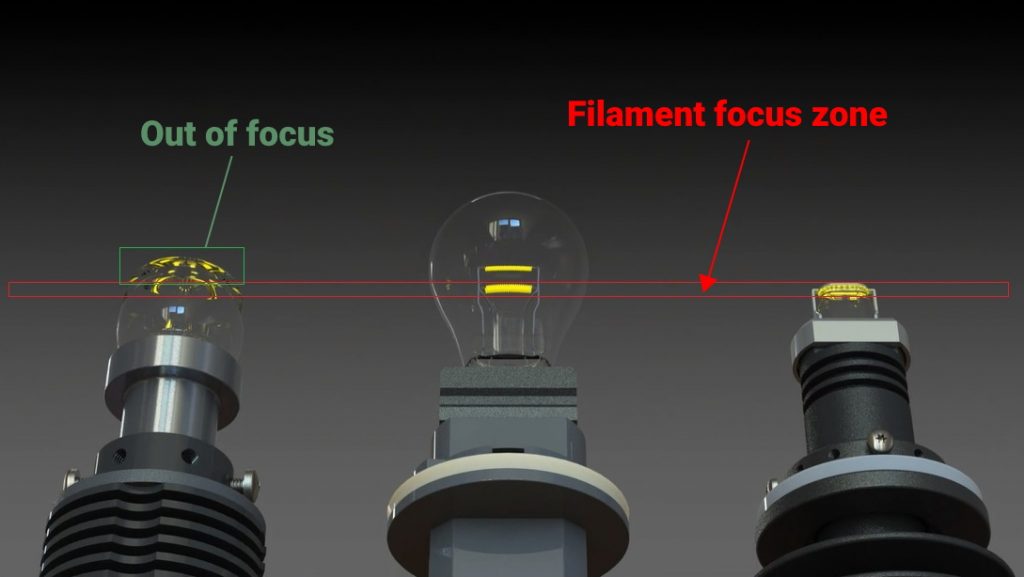

In this rendering image comparison below we can see the VLEDS Triton, 3157 incandescent bulb and XTR VF LED side by side. Within the red box is where the focal point axis is to the filament. At this angle you can see how the XTR VF LED optic matches more closely in size to the filament than the VLEDS which has a longer wider ridge.

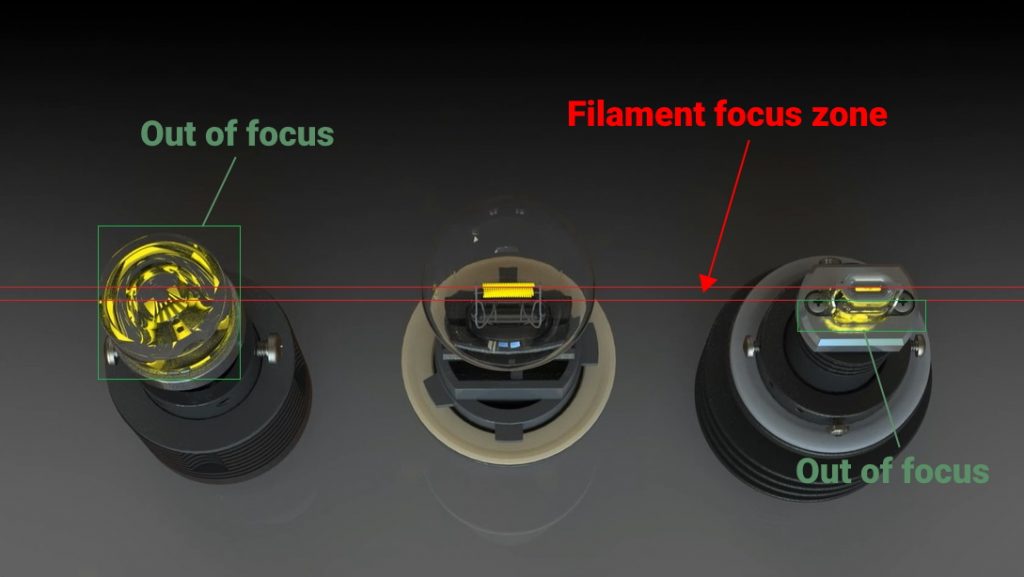

In this next view from the top there is a “out of focus” area in green. The XTR VF LED has some leaking light in this area but the VLEDS has a much larger unbalanced forward illumination. Most of the VLEDS illumination is fired forward through the top of the optic and is NOT used at all inside the lamps reflector.

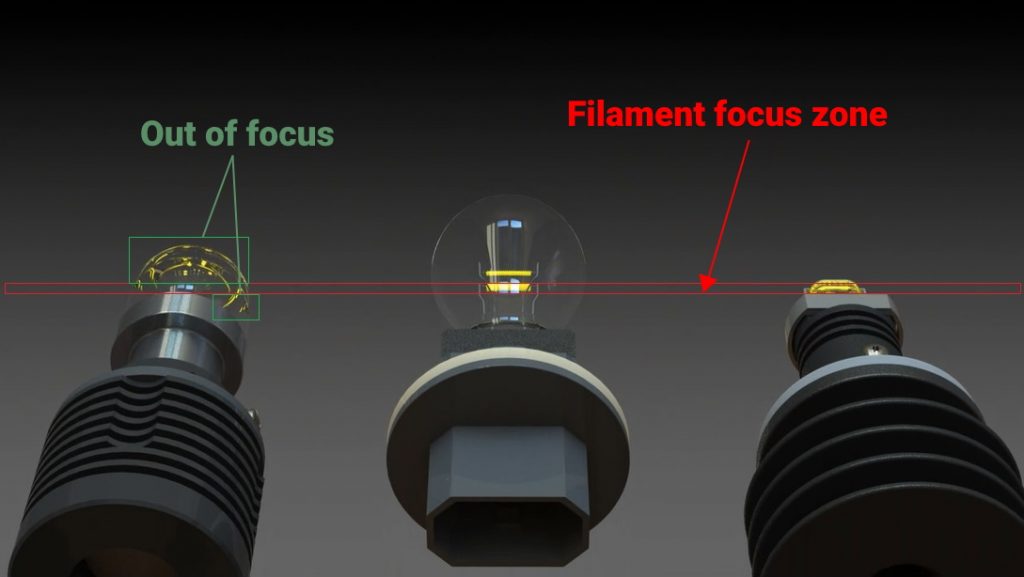

As we move toward the back viewing angle we can see where the VLEDS starts to show its weakness in the design. The central focus zone falls over an area of the optic that has poor lumen density while the XTR VF LED remains strong.

And finally this rear angle is where the sweet spot of the lamps reflector produces the highest intensity in the beam pattern. The XTR VF LED has great back shoot illumination due to the reflector cup inside the optic. The VLEDS is at its worst focal point along the central focus zone and its virtual lighting point is scattered.

Despite both bulbs utilizing virtual filaments their execution in design is vastly dissimilar. The XTR VF LED is more in line optically with that of a traditional filament which in turn should result in parallel optical performance. The VLEDS on the other hand shows an unbalanced optical design with light ejection characteristics that don’t really mirror that of the original bulb. Reflector focus efficiency is important because when the LED bulb works just like a filament it will ultimately produce the intended designed beam pattern with high accuracy. A mixed blob of light coming from an LED may appear at close range to be bright however at far range and at multiple angles visibility will be less bright when compared to a bulb that has a focused intensity.

Most lamps have different focal points even if they are using the same incandescent bulb type. Having a fixed focal point for a LED bulb of this design will most certainly result in poor performance across all vehicle platforms. Because the placement of the VF is critical for optical focus conformity it’s imperative that there is adjustability incorporated to the design. Both the XTR VF LED and the VLEDS both have a telescoping feature which allows for the user to manually adjust and fix the position of the VF to match the incandescent filament height of their specific vehicle.

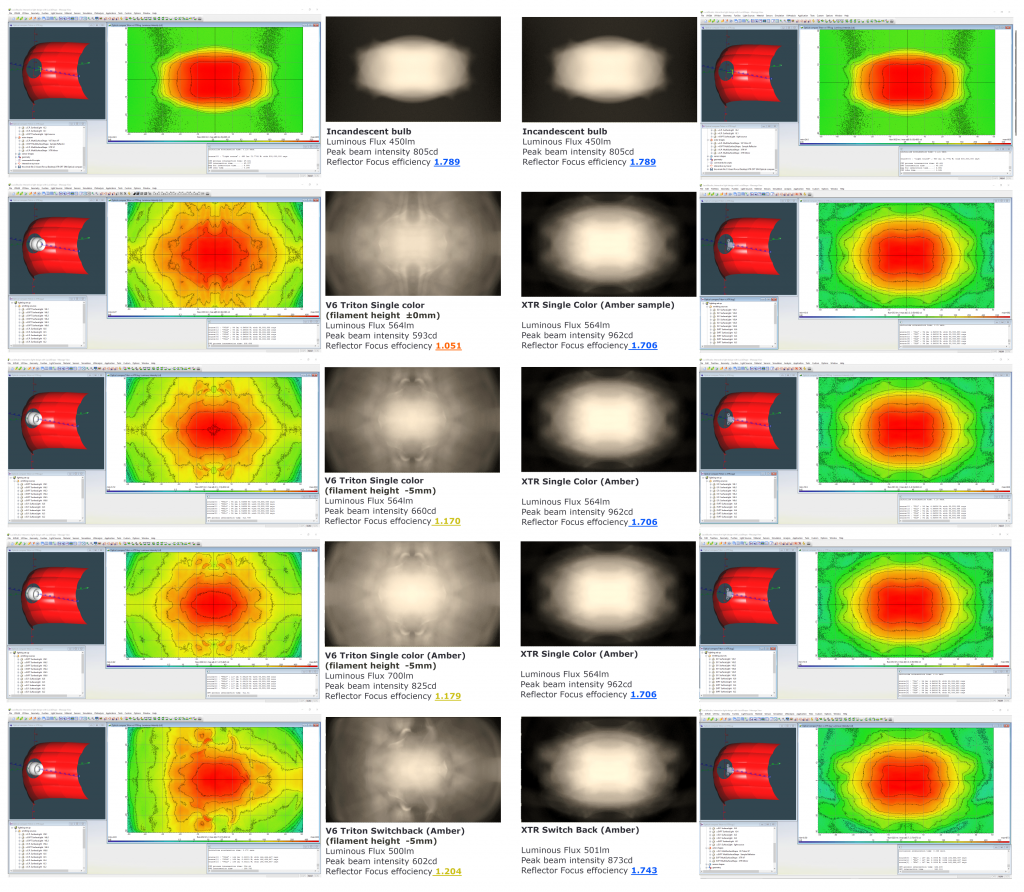

Here are renderings from the optical software during development that illustrate the reflector focus efficiency between both bulbs. For the VLEDS, two separate focal point adjustments were done to evaluate how the effect would be to the beam pattern. The results are quite interesting. Even when the focal point is matched to the filament, the beam pattern doesn’t quite match the original. This also illustrates that an LED with far greater luminous flux over the original incandescent doesn’t guarantee better performance.

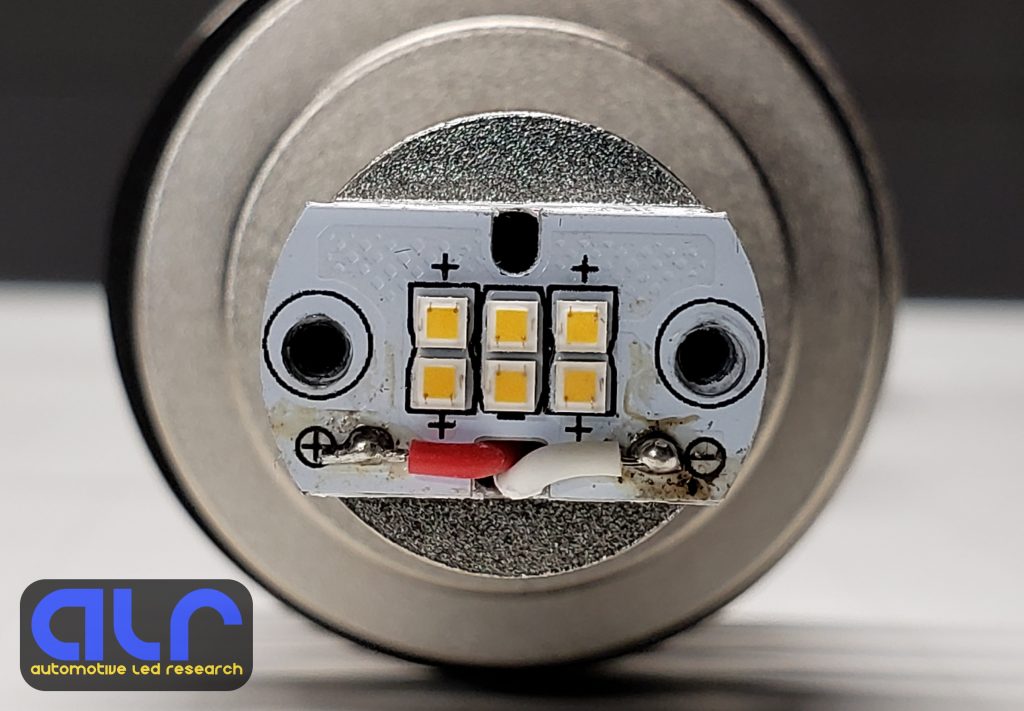

Luminous output for the amber version XTR VF LED is rated at 564 raw lumens for high output mode and 840 raw lumens in hyper-bright mode. It uses 6x Cree XQ-E HI chips in PC amber. As tested, power consumption is about 19W in hyper-bright mode. When the bulb is blinking during turn signal activation the LEDs will be powered at full maximum. If the bulb is used in a headlamp where the turn signal bulb also functions as a DRL, then after 1.5 seconds of activation it will dim by 40% and remain in high output mode. This is to prevent stressing the LEDs over a prolonged period and extends their life.

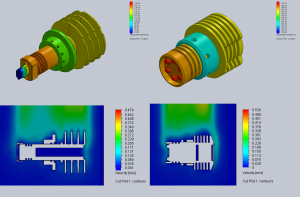

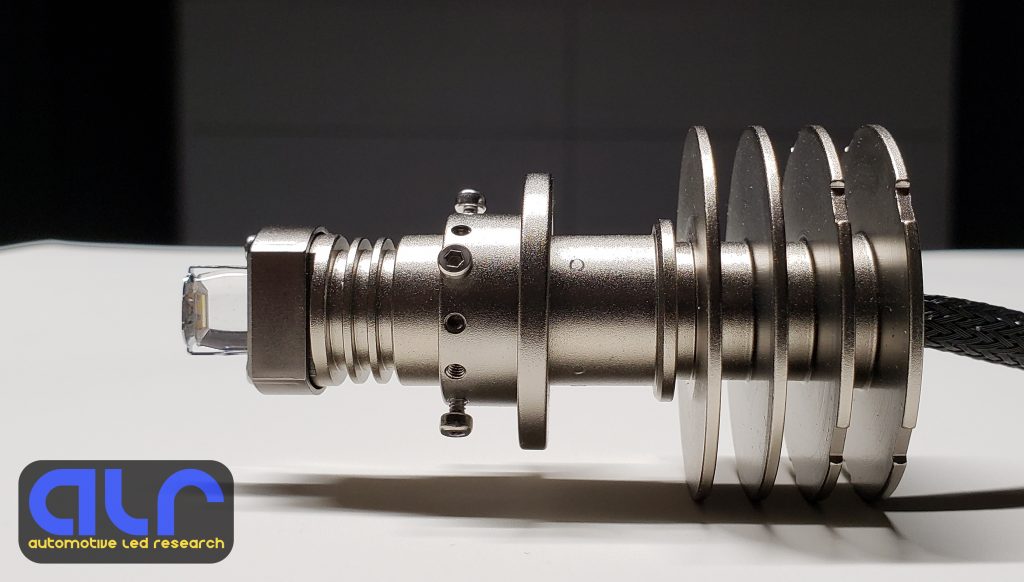

In order for the LEDs to perform optimally and reliably it requires a properly designed thermal system. For this, the body of the bulb is made of an aluminum alloy. Careful consideration was made to keep the overall size compact while maintaining a low thermal resistance. Being passively cooled, attention was placed on the fins sizing and spacing. This is to ensure proper airflow. Taking a look at this velocity simulation chart of both the XTR VF LED and the VLEDS we can observe the differences between how both heat sinks are designed. The VLEDS has smaller circumference fins that are tightly packed which doesn’t leave room for good airflow. And to further impact thermal performance, the VLEDS V6 now includes the driver module inside of the bulb. This adds even more heat to the body. If the LEDs get too hot and reach or exceed their maximum heat tolerance levels then their luminous flux will decrease, their lifespan is shortened and the color could also shift behind their designed spectral output. This is why the driver module is external on the XTR VF LED. It was important that the design of the heat sink body was extremely efficient to keep the LEDs performing at maximum high level and living a long and fruitful life. It doesn’t make much sense to add unnecessary heat to the bulb body and compromise LED performance if you can simply just keep the driver module external. In fact the XTR VF LED went through a 4 week continuous constant operation torture test in a 60°C environment with no reported thermal damage to the components.

of both the XTR VF LED and the VLEDS we can observe the differences between how both heat sinks are designed. The VLEDS has smaller circumference fins that are tightly packed which doesn’t leave room for good airflow. And to further impact thermal performance, the VLEDS V6 now includes the driver module inside of the bulb. This adds even more heat to the body. If the LEDs get too hot and reach or exceed their maximum heat tolerance levels then their luminous flux will decrease, their lifespan is shortened and the color could also shift behind their designed spectral output. This is why the driver module is external on the XTR VF LED. It was important that the design of the heat sink body was extremely efficient to keep the LEDs performing at maximum high level and living a long and fruitful life. It doesn’t make much sense to add unnecessary heat to the bulb body and compromise LED performance if you can simply just keep the driver module external. In fact the XTR VF LED went through a 4 week continuous constant operation torture test in a 60°C environment with no reported thermal damage to the components.

Now that we’ve reviewed the features and key design elements lets move on to the next phase – first impressions.

Already ready for part 2. Great work as usual